Quick link: If you need some of these pickup covers for your project, you can grab these from my store here.

When I first met Lee Jeffriess, he was playing bass in a Hawaiian swing band that I perform with called the Alcatraz Islanders. What I didn’t know at the time is that he was a steel guitar legend and a former member of the fantastic Big Sandy and the Fly-Rite Boys during some of their best years.

Go ahead and put this on while you’re reading this, why don’t you?

As I got into steel guitar playing myself and combed through the Steel Guitar Forum for tips on this unforgiving instrument, it soon became clear that not only was Lee a monster player, he was the authority on all things vintage steel. That included history, technique, gear, recordings, and other minutiae like tone capacitor values. Many informative threads ended with something to the effect of, “That’s what I think anyway, but Lee Jeffriess would know for sure.”

So when Mr. Jeffriess, knowing I’ve been getting into this 3D design thing, asked if I could make a pickup cover for Fender Stringmaster T8 pickups, I knew that there was absolutely no other way to get them. A quick googling pointed me to aforementioned Steel Guitar Forums, which confirmed this. Ironically, you can still get modern reproductions the pickups themselves… just not the covers!

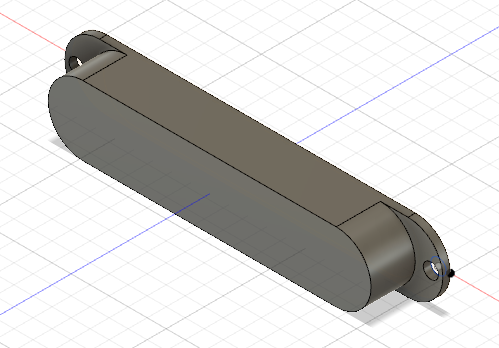

Lee said he’d bring me an original one to copy, but since we see each other sparingly, I thought I’d design it “blind” to get the jump on it and surprise him at the next gig. Design-wise the modeling of the part wasn’t hard. It’s a simple slot shape extruded and shelled.

From some research, I knew that the width and shape was the same as a standard fender 6-string single-coil. So I looked up the dimensions of those online, then lengthened the size to accommodate 8 strings according to the online specs from repro pickups offered by Lollar and Seymour Duncan. Printed out, it looked like this:

The fuzzy look on the sides is due to poor adhesion to the support material. A model like this one must have temporary support structures to help with the overhanging sections, but I figured this was passable since those would be obscured under the pickup housings when installed.

The next time I saw Lee, he pulled out an original T8 pickup cover and handed to me, reminding me that it was something he was still interested in having me work on. I replied, “Well, I’ve got a present for you,” and handed him back my complete printed model, smiling and feeling rather impressed with myself. How’s that for turnaround time, right?

Lee took it looked at it for perhaps 3 seconds, frowned a bit, and remarked that it pretty close, but the mounting holes were off and the ribbed texture on the top would not do at all. Flashbacks of my father’s look of disappointment from A- report cards suddenly came flooding in. Overall though, a good start, he offered. He would take the prototype and see what he could do about making it look more polished.

I took the original home and adjusted the measurements. I was pretty close, but no cigar. He was right, the mounting holes were misplaced and it was also slightly too long lengthwise. A quick adjustment to the design righted that. It’s always good to set up your design projects to take adjustments easily without shitting the bed. No one gets it right the first time.

I printed a couple more prototypes out, but then it occurred to me to try rotating the model on the print bed so the grain lines would run lengthwise, which would look much cleaner. I also flipped it over vertically so that the support structures would be inside the cover to smooth out those mounting hole areas. It took more time to print and used more material, but quality was much better. A valuable lesson that small changes in all parts of the production process can add up to big improvements in the final product.

Personally, I found it to be passable in quality. Once installed, someone would have to be looking real close to notice anything amiss and if he/she did actually take issue with it, 95% chance that person is Lee Jeffriess.

Meanwhile, on his end, Lee carefully sanded the prototype and quadruple coated it with a special brand of spray paint and hit me back with this:

I’d call that pretty legit! Nice teamwork here.

Update!:

If you need some of these for your project, you can grab these from my store here.

A photo of my covers installed in a customer’s Stringmaster (thanks Quintin!):